Linear AMS, A Shapeways Company, Talks with CompositesWorld About Composite Tooling

David Myers, New Business Development Manager, recently spoke with Peggy Malnati of CompositesWorld about advances in composite tooling.

David Myers, New Business Development Manager, recently spoke with Peggy Malnati of CompositesWorld about advances in composite tooling.

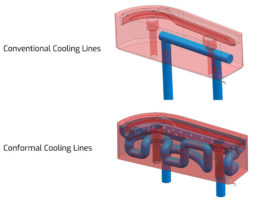

The article also details how Linear AMS “has used multiple metal AM technologies to produce conformally cooled inserts for its injection molds since 2005.”

A good example of the type of complexity that Linear regularly produces with its conformally cooled inserts is the mold for a high-voltage electrical insulator used by the New York Transit Authority on railways for switching tracks. Reminiscent of a giant mushroom, the 123-millimeter-diameter x 270-millimeter-tall part is injection molded using 60 grams of 60% fiberglass/mineral-reinforced polybutylene terephthalate (PBT). The conformally cooled insert takes up nearly the entire core geometry of the single-cavity, oil-cooled tool, which was designed to produce three different insulators in three different lengths, which are selected by changing inserts.

This CompositeWorld article is a great introduction to understanding how manufacturers are using some of the latest metal additive manufacturing technologies, including:

- Direct Metal Laser Sintering (DMLS) and solidification

- Wire-arc Additive Manufacturing (WAAM)

- Additive Friction Stir Deposition (AFSD)

Do you have manufacturing projects coming up in 2023 that might require advanced composite tooling?

To find out more, reach out to David and the Linear AMS team at: sales@linearams.com .