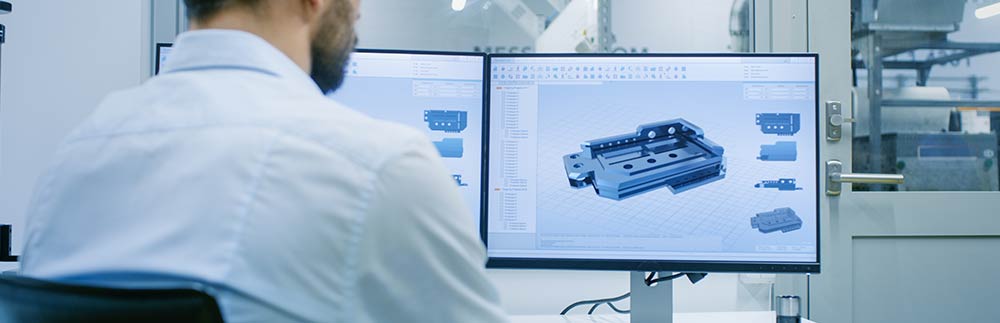

Innovative Manufacturing Solutions that Make Better Parts, Faster

From design to production, bringing your project to life can be challenging. You want to identify the best suppliers, materials, and equipment available. Or, you may want to optimize your existing production for price, efficiency, and quality. Linear, a Shapeways Company, is your manufacturing partner. We support end-to-end industrial processes from design to prototype to production.

We consult with our clients to design manufacturing solutions that utilize traditional methods like injection molding as well as the latest innovation within additive manufacturing. Long-time customers rely on our technological expertise and certifications to deliver shorter cycle times, increased profitability, and world-class customer service.

We consult with our clients to design manufacturing solutions that utilize traditional methods like injection molding as well as the latest innovation within additive manufacturing. Long-time customers rely on our technological expertise and certifications to deliver shorter cycle times, increased profitability, and world-class customer service.