Thermoplastic Molding

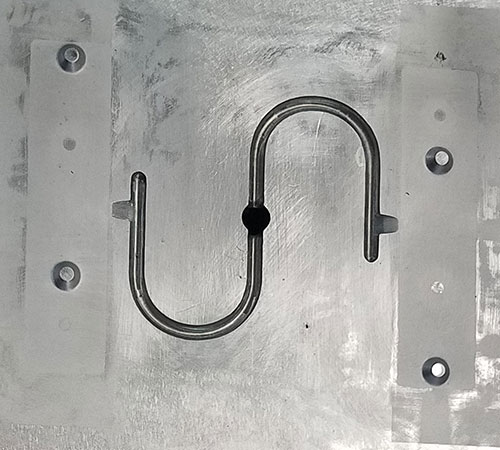

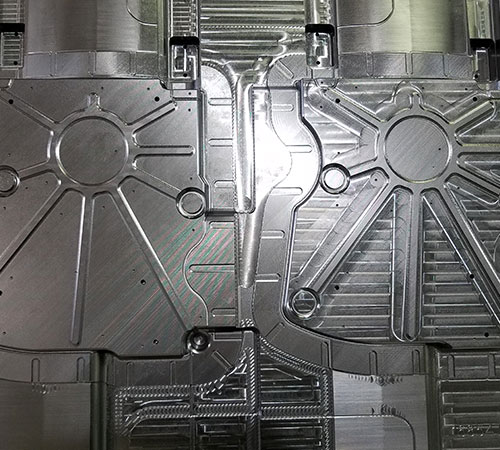

Injection molding is a manufacturing process for producing parts by injecting plastic resin into a mold. This process is one of the most common ways to produce large volumes of finished parts for many different uses. Aluminum molds typically produce anywhere from 5-5,000 pieces. These molds can be acid etched, grained and typically offer better thermal properties than steel tooling for production quality parts. Whether it be for prototyping, low volume, or high volume production, we can provide a solution designed to meet your plastic part production needs.