Fastest Turnaround

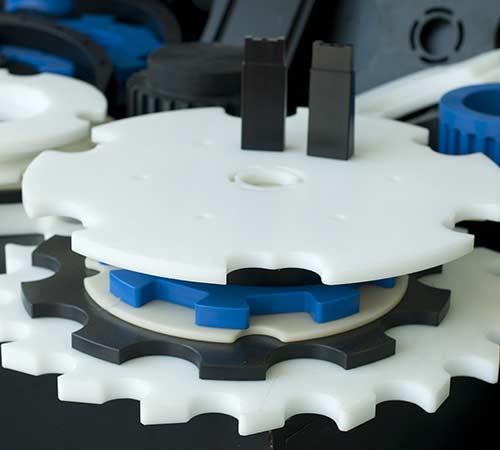

Quickly fabricating any 3D model is easier than ever with our advanced technologies. Our 3D printing applications allow for a fast turnaround. We specialize in additive layer manufacturing which also allows for the design and build of these intricate prototype parts. Our CAD workflows enable us to edit designs so you can continue to re-configure your prototype as the design process advances. Find out more about the systems we use to deliver high-quality prototyping parts.