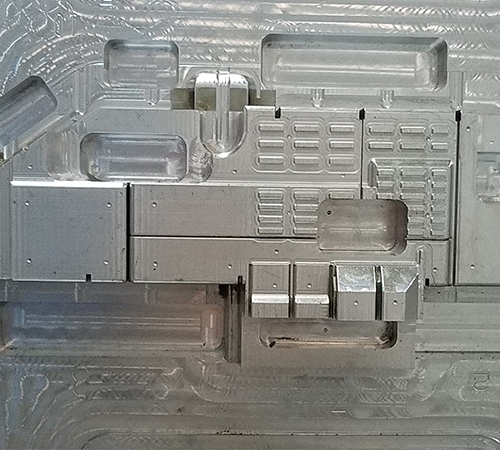

Quality Builds

Our tool building specialties include prototype injection molds, production injection molds, compression molds, and bridge tooling making us complete metal AM/conformal cooling experts. All of these services allow us to shorten production time for our customers and increase the overall product quality that we can offer them. Linear is uniquely positioned to offer innovative tooling solutions, competitively, in our growing marketplace.